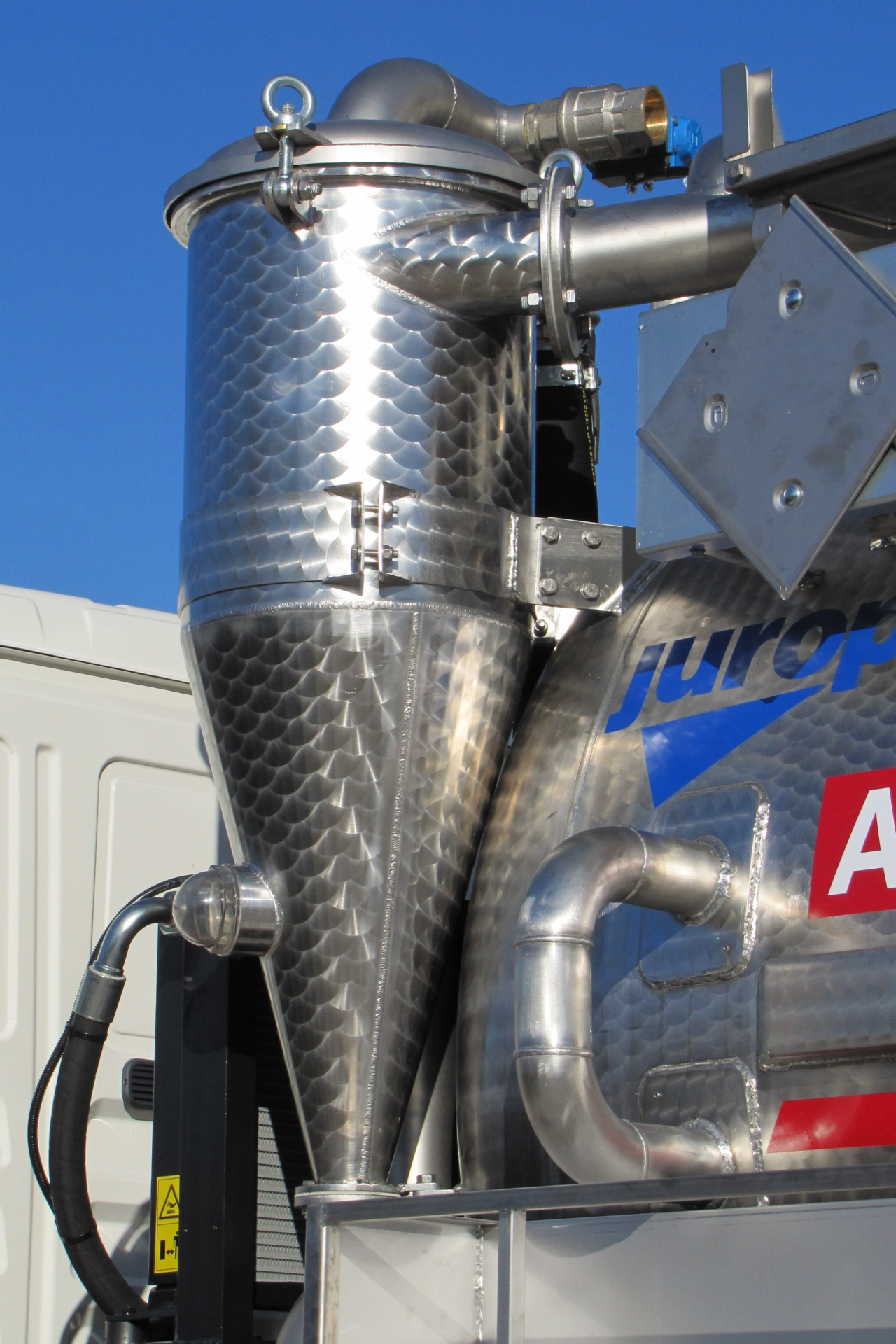

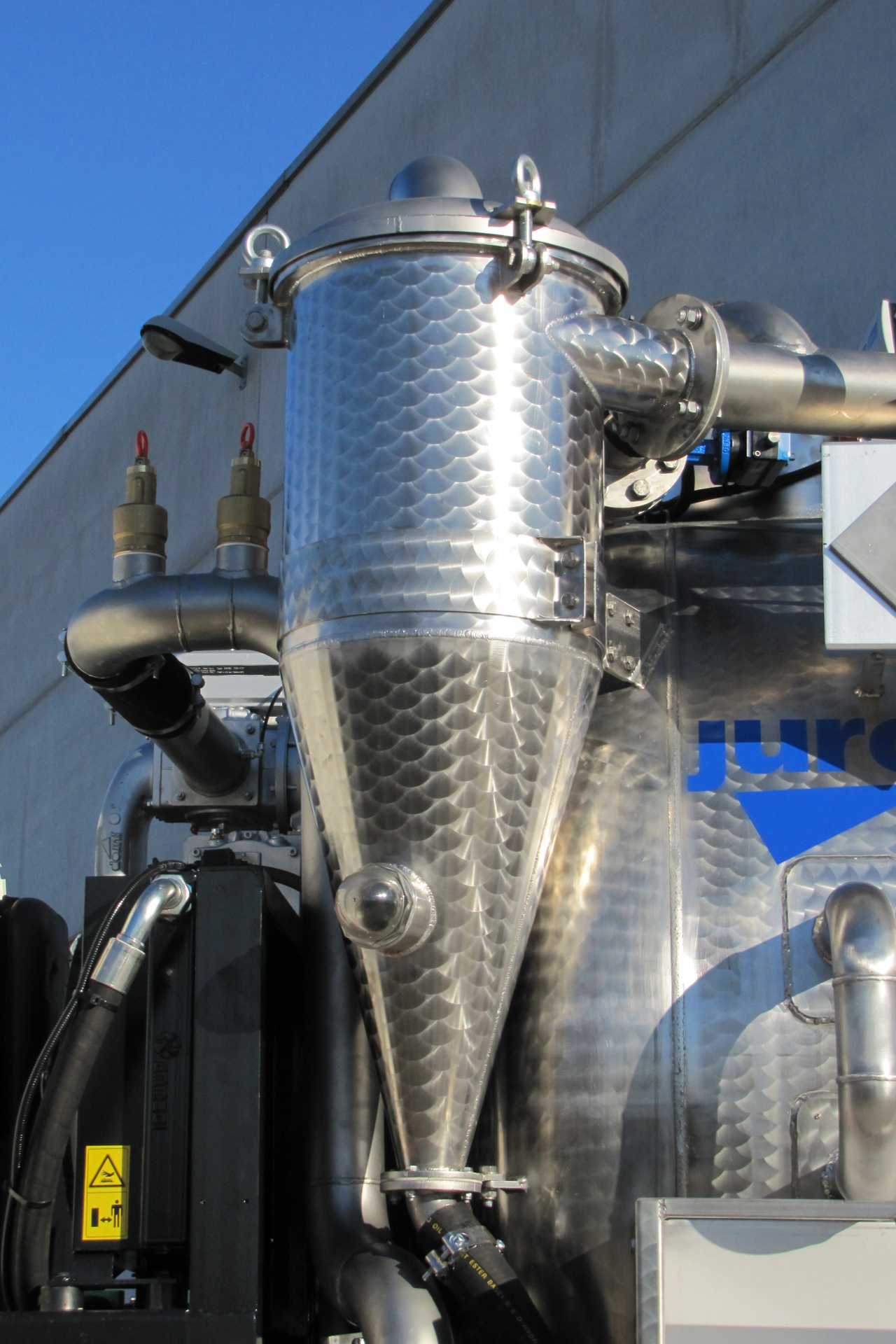

The PR cyclone secondary shutoffs and moisture trap are designed to be installed in correspondence with the intake line of decompressors used to create vacuum inside tanks. The cyclone secondary shutoff and moisture trap prevents foreign bodies (liquids or solids) that could carry over past the primary shutoff from entering inside the decompressor by blocking the intake line with a stainless steel floating ball. The cyclone consists of a vertical cylinder, which tangentially receives the flow to be scrubbed at high speed. As a result of centrifugal force, the various elements contained inside the fluid are separated according to their density. The purified fluid is freed through the upper axial outlet, whereas the material to be recovered is collected in the lower tapered part of the cyclone and discharged after each job.

.jpg)

.png)