_-_Immagine_Istuzionale_-_01.jpg)

_-_Immagine_Istuzionale_-_01.jpg)

Via Cadore no. 13

The business was launched in 1976, in an industrial building in Villotta di Chions. The flow rate of the first models reached 6500 l/min (390m3/h).

P the first decompressor

The decompressors of the P series, air cooled, were the first to be marketed by the company. The flow rate specifications, from 3000 to 6500 l/min, allow them to be specifically used in agricultural applications.

The company expands

A few years later, the first JUROP production facility was inaugurated in Azzano Decimo, for the production of purging solutions.

Functionality comes first

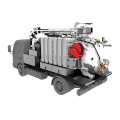

The purging equipment are made for undercarriages, trailers and semitrailers, fixed or roll-on, they use vacuum pumps produced by JUROP.

Tornado: a breath of fresh air

TORNADO, the leading equipment in the field of extraction, is launched in 1983.

Silence and efficiency have a name: JP

This is a rotary lobe pump used for filling, mixing, emptying, irrigating and draining liquids. The flow rate specifications of the JP series range from 1420 to 5100 l/min.

A partnership with the Italian State Railways (FS)

The project entails production of three different types of outfitting for cleaning and emptying the storage tanks holding the sewage from train toilets.

ADR: collection and transport of hazardous waste

This type of equipment for collecting and transporting hazardous waste is also suited for separate collection thanks to the tank with multiple compartments constructed in stainless steel.

Roll-on/Roll-off

Roll-on/Roll-off equipment is designed and produced for customers interested in diversifying their activity without being forced to increase the number of vehicles.

VJ TRONIC

VJ TRONIC is the first and most innovative electronic system for controlling equipment. The result is to simplify the operator’s work and to optimise usage of the system, achieving previously unthinkable levels of efficiency and energy saving.

Patented injection system

The PNR/PNE vacuum pumps/compressors use construction principles that until then were exclusively applied in industrial pumps.These are rotary, sliding vane vacuum pumps cooled with air injection (PNR models) or natural convection (PNE models).

The Recycling System of the new millennium

The Recycling System enables a percentage of suctioned water to be reused. Moreover, the system enables the thickening of sewage and the consequent transport of larger amounts of solid materials containing minimum percentages of water.

The new PVT pump serie

PVT vacuum pumps are 3 lobe blowers specifically designed for vacuum plants that must convey gas free from polluting substances, oil or water.

The new PVT pump side injection system

This new system allows the noise pollution arising from use of the decompressor to be reduced, with significant savings in terms of encumbrances and costs resulting from the soundproofing systems required otherwise.

Cooling impellers

RV and RVC are rotary vacuum pumps with forced air cooling by means of two juxtaposed, high efficiency impellers. Use of the impellers makes it possible to significantly increase the continuity and service life of the pump.

Patented cooling

Starting from 2014, the entire DL series undergoes restyling. The decompressor with three-lobe rotors in synchronised rotation uses an innovative cooling system with built-in check valve.

SYNC

JUROP patents SYNC, a set of accessories for pipe guiding and support, in equipment used for collecting and/or processing waste thanks to the simultaneous rotation of two accessories.

Helical tri-lobe lobes

An innovative aspect of the new VL is the helix-shaped lobes, which ensure liquids and sewage are conveyed without any irritating flow pulses.

HELIX

The true novelty is the HELIX series. The special helical shape of the lobes assures smoother motion, without any vibrations at all.

VL-Evolution

The VLE is a 3-models series, featuring a new buffer chamber providing enhanced protection against media infiltrating into the gear box.

Compact recycling module

The recycling system enables a percentage of suctioned water to be reused thanks to the separation of a large part of the solid particles in suspension, which could otherwise damage the high-pressure pump and pipes.

ITALA

ITALA is a gearbox suitable for driving a DL vacuum pump and a torque flow centrifugal pump by the same power take off.

IDROVAC

The Idrovac Jurop excavator is an advanced technology equipment, particularly suited to be used in construction.

Suction unit

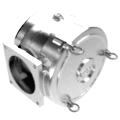

The suction unit is designed to be installed in correspondence of suction/discharge ports and can be installed on the PVT1000, HELIX1200 and HELIX1500 vacuum pumps with horizontal ports.

CTH 880

CTH 880 is a Helical tri-lobe rotary volumetric compressor with synchronised phase helical gears. Low noise level due to the exhaust pressure soft adaptation system.

.jpg)

.png)